FULL-RANGE SEALING WITH MULTI-SEAL

Most trunnion-mounted ball valves have difficulty sealing at both high and low pressures. Balon's Multi-Seal seats provide multi sealing surfaces for full-range sealing. This results in steady operating torques for low pressure applications and high pressure applications. Multi-Seal is standard in every valve.

BLOWOUT-PROOF STEM WITH SAFETY SHEAR GROOVE

To prevent hazardous blowout, the Balon Series T stem is internally loaded and back-seated. And, as an added precaution each stem includes Balon's safety shear groove. If the stem should be inadvertently sheared, breakage occurs at a safe distance from the pressure zone.

LOAD-BEARING BLOCKS

Balon has done away with the externally inserted lower trunnion, a hazardous leak path, a maintenance nuisance, and a blowout point. The Balon Series T incorporates load-bearing blocks. Even at maximum pressure, the blocks bear the load uniformly and reduce lateral stress, keeping the ball centered. Balon has eliminated the premature bearing failure associated with traditional trunnion valve designs.

DOUBLE-BLOCK-AND-BLEED AND SECONDARY SEALING

Every Balon Series T includes a bleed fitting for double-block-and-bleed, and every valve allows grease injection for secondary sealing.

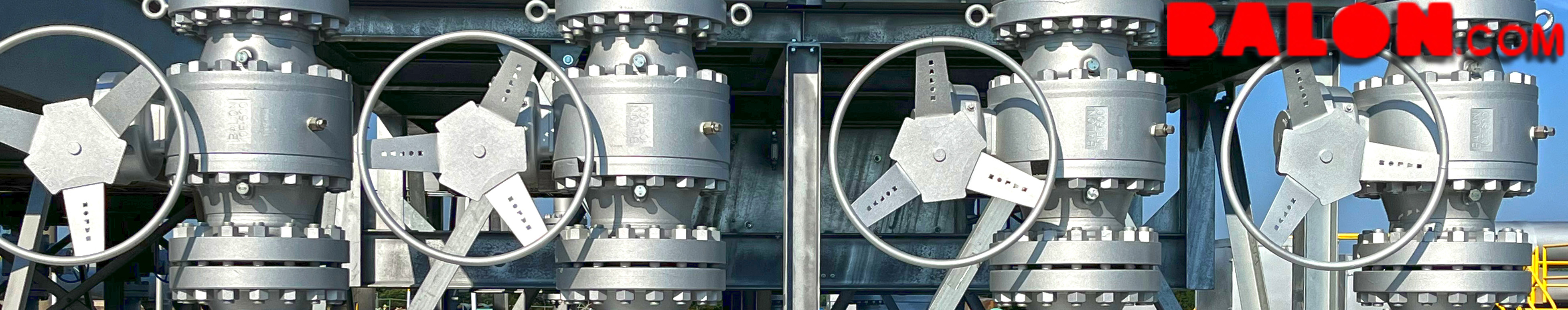

LOCKING DEVICE ON EVERY VALVE

Balon Series T valves, like all Balon gear operated valves, feature standard locking devices in all sizes.

FIRE-TESTED AS STANDARD

With Balon, there is no need to ask for "fire safe." Every Balon Series T ball valve is certified fire-safe per API 6FA.

EMISSIONS TESTED - API 641

Balon trunnion valves successfully completed low emissions testing and are certified low emission per API 641. See Page 12 for more information.

100% AMERICAN-MADE

Like all Balon valves, the Series T comprises 100% domestic raw materials. All machining, assembly and testing work is performed in our Oklahoma City plant by Balon employees.